|

Install Tips

The following is a tutorial on

installation of our most popular model, the YG-101 Swing

Gate opener. Expect to see installation tutorials for

other models as they become available. Note this

tutorial is not a substitute for the manual, read the

manual completely before beginning installation.

This tutorial is divided into

the following sections.

1. Necessary Tools and

Equipment

2. Installation Method

3. Site Preparation

4. Mechanical Installation

5. Wiring the Motors and

Control Box

6. Setup and Tuning

7. Maintenance and

Troubleshooting

1. Necessary Tools and

Equipment

Installing a gate opener is not

an easy job, and is best performed by a professional,

however if you are a serious do-it-yourselfer, this

could be a job for you. You will need some tools before

we get started. You will need standard and phillips

screw drivers, an electric drill, wire cutters and a

wire stripper, a socket set, and access to a welder. If

the bracket parts shipped do not fit your gate because

of the dimensions of your gate, you may also need

equipment to cut and grind metal parts. In some rare

cases you may have to fabricate brackets for your

application.

2. Installation Method

There are basically two ways to

install the YG-101, "push to open", and "pull to open".

The name says it all, either the motors extend pushing

the gate open, or they retract pulling the gate open.

We need to decide first which type of installation this

is. The difference between "push to open" and "pull to

open" is that the gate is mounted on a different side of

the mounting post. for "pull to open", the gate is

mounted inside the posts, while for "push to open", the

motor is mounted inside the posts, and the gate is

mounted on the post face 90 degrees from it. The

illustrations below should help clear things up.

Figure 1

Figure 2

In the illustrations above, the

blue lines represent the gate, and the grey objects are

the gate motors. Taking a look at the enlarged section

may help too. If at anytime this seems unclear you can

email

[email protected]

for help or see our FAQ page here on the website.

3. Site Preparation

Before we begin,

this tutorial will assume that the gate is mounted to

the mounting posts and swinging freely, there should be

little resistance in the swing of the gate. Since both

motors must be powered, a set of wires from the control

box to both motors will be required. Therefore it is

necessary to dig a shallow trench across the driveway.

If the driveway is paved this will require a masonry saw

and chisel. The YG-101 is powered by 110V/60Hz AC

power, therefore if you have not already done so, wire a

waterproof outlet near the gate following proper safety

standards for your area. If you are not experienced

with this type of wiring or if your area requires it,

hire a professional electrician to perform this as well

as wire in the YG-101 in step 6. Once the gate is

mounted adequately, electrical power is available, and a

trench for the control motors is dug, we are ready to

proceed to step 4

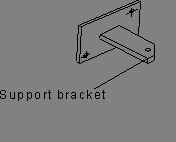

4. Mechanical Installation

Now that the gate

is installed, and power is available, lets install the

motors. First weld part b1 to part b2 as shown:

Figure 3

Then mount the assembly b1-b2

on your post according the figure 1 or figure 2

depending on whether yours is a push to open or pull to

open configuration. Verify that the bracket is mounted

level and square with the post. Make sure that both

gate motors are unlocked by turning the keys supplied.

Mount each of the gate opener motors to the bracket

b1-b2 as shown below.

Figure 4

To

install the rear part of the gate opener, insert

shoulder screw and spacer, then tighten with the nut.

Next

open the gate to its maximum position 90 degrees, and

weld bracket b3 onto your gate. Alternatively you can

drill a hole in bracket b3 and bolt it to your gate.

This area really depends on what gate you are using and

how you want to attach it. Some gate may even include

the bracket hole to mount to and bracket b3 will not be

necessary.

Figure 5

To install the front

part, fit the hole in the front part with the hole in

the supporting plate

b3, and push the axle pin into the holes (using your

hands or a hammer), and finally fit the retainer clip.

See Fig.6.

Figure 6

With the gate motors in their

UNLOCKED condition, you should be able to freely move

the gate from the open to the closed position. If the

motion is not as desired, you may have to rework the

position of one or both brackets to obtain the desired

motion. Do not proceed, until the gate can move from

the open to the closed position with the gate motors

attached.

5. Wiring the Motors

OK, now we have the gate

installed, power available, and the gate opener motors

mounted to the gate. We need to next run wires from the

gate opener motors to the location that you plan to

mount the control box. We suggest you mount the control

box inside your property out of direct sunlight and in a

safe location. The control box should also be in an

area where you can easily access it for the tuning

procedure in section 7.

Obtain a quantity of normal

lamp cord gauge 18-3 available at your local Lowe's or

Home Depot. WARNING, use only 18-3 or better wire to

cable your gate motors. Run the wire from the motors to

the control box. It is recommended that you run the

wire in a PVC or other electrical conduit to protect it

from cuts or gouges. You can also run the electrical

cable from the control box to the 110V outlet in this

manner. See the photo below for an example.

Mount the control box by

removing the cover with a phillips screw driver and

screwing through the mounting holes into a mounting

surface like a post or fence. Make sure it is a sturdy

and appropriate surface. You can leave the cover off

for now while we wire the motors.

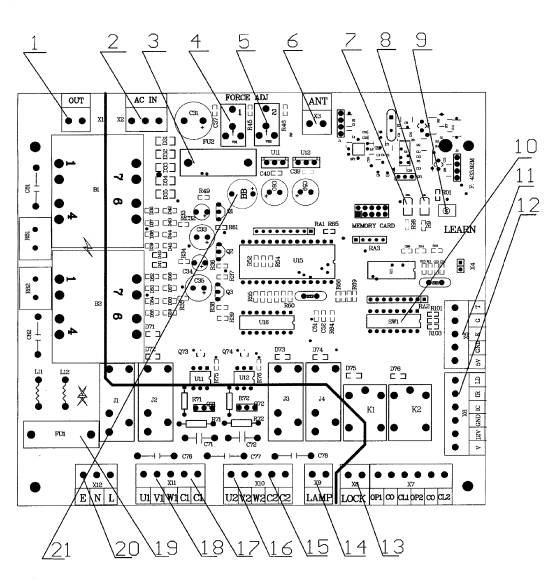

Wiring

Screw off the two

stainless tapping screws, then remove the cover and

wiring as shown in Fig. 6. WARNING: Follow the

wiring diagram precisely. Failure to do so could cause

damage to the gate opener controller.

You will wire from motor 1,

U,V,W contacts to block 18, contacts U,V,W and from

motor 2 U,V,W to block 16 U,V,W. See table and circuit

diagram below. It does not matter which motor you

decide to be motor 1 and which you designate motor 2.

It is a good idea to use one color wire for U, one for V

and one for W. For instance if you wire contains black,

white, and green then you might use U=Black, V=White,

and W=Green. Just remember to wire them correctly

because mis-wiring could cause DAMAGE to the gate

controller.

|

No.

|

Tag

|

Remark

|

|

1

|

U1

|

No.1 motor: COM/U

|

|

2

|

V1

|

No.1 motor:

V

|

|

3

|

W1

|

No.1 motor:

W

|

|

4

|

U2

|

No.2 motor: COM/U

|

|

5

|

V2

|

No.2 motor:

V

|

|

6

|

W2

|

No.2 motor:

W

|

IMPORTANT SAFTEY

INFORMATION

Installing the YG101

Gate Opener requires wiring of standard AC 110V

electrical lines. This should only be performed by a

trained technician. In some areas, it may be required

that a licensed electrician perform these steps. Mis-wiring

could cause personal injury or DEATH. To prevent the

risk of electrocution, be sure to turn off all power to

the YG101 until installation is complete.

Once the gate openers are

wired to the controller box, we are ready to wire the

control box to your electrical outlet. Using the 18-3

gauge electrical wire, wire a standard grounded plug

(available at Lowe's or Home Depot) to your Gatekeeper

control box using standard electricians wiring

practices. Wire the opposite end of this cable to the

E, N, L contacts of the YG-101 control box. Connect L

to the power or black line, N to the neutral or white

line, and E to the ground line. At this point, we

should be ready to fire it up, plug in the control box,

and turn the locks to the lock position on both gate

motors. If the lock will not turn, then do not force

it, this could cause the key to break. If the lock will

not turn, then it is because the motor is under load,

perhaps the attachment between the motor and the gate is

misaligned and putting it under load, remove the load

then lock the gate motor.

6. Setup and Tuning

Now that

everything is setup, lets allow the gate to learn its

remote controls:

Press the red

learn button on the control board, the LED will turn

on. It will turn off when you press any button on the

transmitter. Press the same button and the LED will

flash with a 2Hz frequency. If the learning process

fails for any reason, the LED will turn off after

flashing for 1 second. If you need to erase the codes,

press and hold the red button on the control board until

the LED stops flashing. After once second, it will

flash again, this indicates that the remote controls

have been erased.

The gate should be

opening and closing with the push of a button now, push

once to open, once to close and pressing the button

while it is moving will cause it to stop.

Now it is very

important that you tune the safety reverse function on

your gate opener.

You must use a

screw driver to rotate the Force Adj. knob. Rotating

clockwise will increase the resistance needed to trip

the safety reverse function. Rotating counter-clockwise

will decrease the resistance. If the gate does not move

when activated, the resistance setting may be too

little. If the gate does not stop when an obstruction

is placed in its path, then the setting may be too

high. Start with just above the minimum value, and tune

it to use the minimum setting for which the gate will

function.

WARNING: Do not

attempt to tune the gate by placing your hand, arm or

other body part in the path of the gate, serious injury

could result. Also placing a heavy immovable object in

the path to test with could cause damage to the gate

opener motors. Instead, place a light object in the

path, preferably something like a chair or trash can

which will be pushed out of the way if the setting is

still too high without causing damage to the gate

motors. Note, this auto reverse function should be

regularly inspected and adjusted if necessary. Now that

the tuning is complete you can replace the cover.

Congratulations,

your new gate opener is installed!

7. Maintenance and

Troubleshooting

Note:

If the gate running direction is not correct, please

change wires .V1 and

W1.or .V2 and W2..

If the wiring between two gates is wrong and the gates

cannot work,

please check the wiring between .U1, V1, W1.and .U2, V2,

W2..

Check

the screw lubricant and add 1# grease regularly.

Keep opener

clean at all times.

If you are still having

trouble, email

[email protected]

for help.

Thanks

The Gatekeeper Team.

|